more

Pulsepedia

Everything you always wanted to know about pulse flours and proteins

Welcome to Ingredion’s Pulsepedia

An easy to navigate, practical reference tool designed to provide you with everything you need to know about pulse-based flours and proteins. With consumer interest in nutritious, high-protein foods increasing rapidly, there is a real opportunity for the food sector to develop and deliver great tasting, protein-rich products using plant-based protein from pulses.

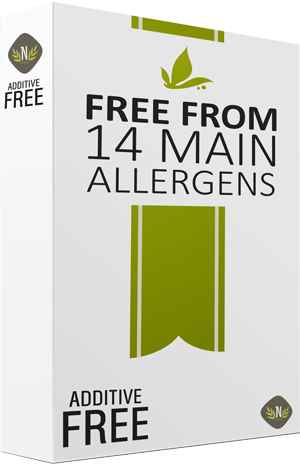

Find out more about the properties of pulses and how pulse flours and proteins can be formulated into clean label recipes to support claims with genuine consumer appeal - from ‘source of protein’, ‘high-protein,’ natural and additive free to gluten-free, vegan and free from 14 common allergens.*

Pulse Properties

*Free from substances causing allergies or intolerances as listed on Annex II of Reg (EV) 1169/2011, food information for consumers.

What are pulses?

The term ‘pulse’ refers to the dried seed of plants from the legume family, like dried peas, dried edible beans, dried lentils and dried chickpeas. It is the special properties of pulses which makes them particularly suitable for today’s health-conscious consumer. They are naturally very high in protein, containing between 20% - 25%, which is nearly twice the amount of protein of traditional cereal crops such as wheat.

How big is the demand for products using pulses? What is driving this growth?

There has been a surge in demand across Europe for products incorporating pulses in the last few years as an increasingly health-conscious population look for more nutritious and nature-based foods.

As part of the healthy lifestyle trend, there is growing consumer interest in nutritious foods that are high in protein. Adding pulse flours or proteins is a great way to create high protein foods whilst also enabling manufacturers to reduce the dairy or meat content of their products.

Alternative plant-based sources of protein are in demand as consumers increasingly consider them to be healthier than meat. The rise of so-called ‘flexitarians’ (people who eat a predominantly vegetarian diet but do eat meat too) is further fuelling demand for protein-rich vegetarian foods as meat consumption is consciously reduced to a weekend only, 5 days vegetarian, 2 days meat-eating approach.

The combination of savvy manufacturers and the emergence of greater ranges of pulse-based ingredients suitable for new and exciting applications, such as Ingredion’s HOMECRAFT® pulse flours and VITESSENCE™ pulse protein concentrates, has helped to satisfy the growing demand for healthier, protein-enriched, vegan foods. Explore how new and existing ranges of snacks, bread, biscuits, cereals, batters and breadings, pasta, soups and sauces can benefit from pulse-based flours and proteins and be part of this opportunity.

What sort of on-pack claims do pulse flours and proteins support?

Nutritional statements help differentiate your products and improve their consumer appeal and commercial success.

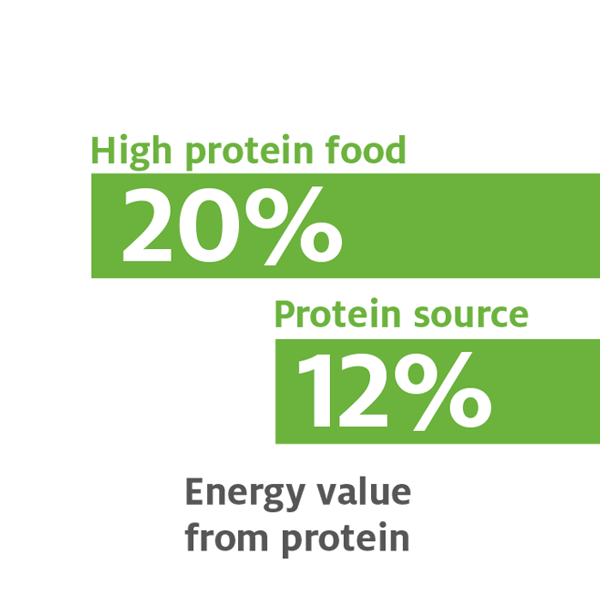

Adding pulse flours and proteins to products supports nutritional claims such as ‘source of protein’ (12% of the energy value of the food provided by protein) and ‘high-protein’ (20% of the energy value of the food provided by protein) and appeals to consumer interest in protein-rich products.

Health claims such as ‘protein is needed for normal growth and development of bone in children’ or ‘protein contributes to the maintenance of muscle mass’ can also be made if 12% of the energy value of the product is from protein.

Our pulse ingredients are naturally gluten-free. They are ideal to support the growing free from trend, which doesn’t just interest people with allergies or intolerances.

Keeping ingredients listings simple is also achievable with pulse flours and proteins, supporting a natural and additive-free claim on pack. Flour is perceived as a kitchen cupboard ingredient and this familiarity is an important influence in consumer purchasing behaviour of food and beverage products.

In fact, pulses can help you achieve a wide range of claims including vegan, free from 14 common allergens*, meat-free, kosher and halal, to improve the commercial viability of your products.

Which applications are suitable for pulse flours and proteins?

Pulses can be milled into flour and together with pulse proteins, they are very suitable for producing and enriching nutritious snacks, bread, cakes, cereals, batters and breadings, pasta, soups, sauces and dips. Different types of pulses like lentil, bean, chickpea and pea, and different particle sizes will suit different applications, so it is important to understand which type of pulse flour or protein is appropriate for your product.

The applications of these pulse flours and proteins are diverse, ranging for example from products, such as high-protein lentil crackers, gluten-free cookie or pasta, to veggie burgers.

Pulse flours, such as Ingredion's HOMECRAFT® Pulse flour can be used across a range of applications, including:

- Protein-enhanced healthy snacks

- Batters & breadings

- Gluten-free products

- Baked products

- Savoury sauces and prepared meals

- Extruded products such as pasta and ready-to-eat breakfast cereals

Pulse protein concentrates, such as Ingredion’s VITESSENCE™ Pulse pea protein can deliver a range of functional benefits, including:

- Pulse-based labelling, originating from yellow pea

- Protein content: 80% minimum dry basis

- Non-soy plant-based protein

- High functionality like solubility, emulsification and water-binding properties in food and beverage applications

- Low flavour profile in raw and green pea notes.

How do pulse flours and proteins perform in the manufacturing environment?

Are there any tried and tested success stories?

Pulse flours are easy to use and can be processed with minimum formulation work. They also have the advantage of ease of storage over a long period of time, making supply straightforward and reducing wastage. Manufacturers,

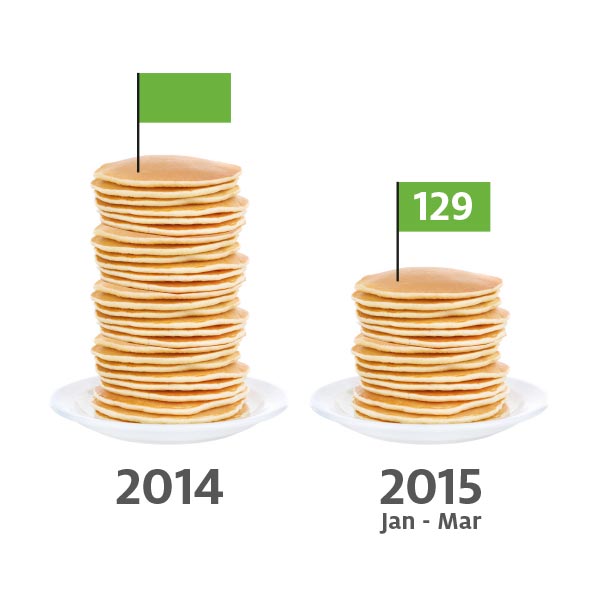

retailers, chefs and the food services sector in Europe are taking on board the positive properties of pulses with 299 finished food products using pulse flours launched in 2014, and a further 129 between January and March

2015*.

*Source: Mintel, GNPD

How easy is it to formulate recipes to include pulse-based products?

Is it possible to taste food prototypes to understand flavour and texture profiles better?

Developing products with protein claims is an unmissable commercial opportunity. Look for a supplier with the right applications knowledge and experience to speed up time to market, as well as the technical expertise and support to make the transition from prototype to large-scale production straightforward and cost-effective.

Ingredion provides pulse ingredients alongside in-depth applications capability to support your decisions on recipe development. Our team of in-house chefs and food technologists is uniquely experienced to work with customers to help them develop delicious formulations across a range of applications and functionality. The advantage of Ingredion’s development kitchens and in-house chefs to help you create product prototypes, gives you a greater freedom to try out new and diverse recipes. This helps remove the trial and error of product development and minimises risk when transferring to the complex processes of the manufacturing environment.

Being aware of the different properties of pulse flours and proteins and which is better suited to a particular application is a key factor in successful product (re)formulation. For example, faba bean flours have a higher protein content and produce crunchier snacks than lentil flours, while chickpea flours work well in bakery products adding moisture through their higher fat content. Combining this product and application knowledge is the key to successful formulations containing pulse products.

What do I need to know about quality and consistency of supply for pulse-based flours and proteins?

Consistent end product quality is essential to avoid batch wastage and any negative effect on your brand. Look for homogeneity to guarantee batch to batch consistency. Suppliers that derive their pulse ingredients from a single variety per product can deliver this, ensuring your end products are consistent in taste and colour to satisfy consumers in all areas.

Continuity of supply will avoid production delay and provide the flexibility to meet seasonal up-lifts.

Ingredion’s HOMECRAFT® pulse flour and VITESSENCE™ pulse protein concentrate ranges are naturally gluten-free, and offer continuous supply and micro-testing of every batch.

Pulses at a glance

Pulses contain 20%-25% protein, nearly twice the levels of protein of traditional cereal such as wheat

Pulses boost the nutritional profile of formulations, supporting claims of ‘source of protein’ and ‘high in protein’

Pulses support a natural and additive-free as well as gluten-free claim

Pulses are store cupboard, clean label ingredients

Pulses enable further claims such as vegetarian, free from common allergens, meat-free, kosher and halal

Pulse-based flours and proteins are suitable for a range of application including snacks, breads, biscuits, cereals, batters and breadings, pasta, soups and sauces

Pulse ingredients can vary in quality – check for homogeneity, particle size and skin removal process to for consistency in production.

For further information contact Ingredion:

Ingredion Germany GmbH +49 40 239 150

Ingredion UK Ltd +44 (0) 161 435 3200

Visit our website